My latest photo story is a slightly unusual one. Taken on my travels around South America, I visited Fray Bentos, home to a fascinating industrial World Heritage Site which exported meat and meat extract for 120 years.

If I mention Fray Bentos to people in the UK, they are most likely to think of the tinned pies still available in grocery stores today. What they may not know is that the brand is named after a small city in Uruguay, which became known as the ‘the world’s big kitchen’ as it sent products to America and Europe, including feeding troops and armies during the Great War and American Civil War.

Uruguay is one of the largest meat producing countries in the world, and raises more cattle per capita of the population than anywhere else. Fray Bentos can be found near the border with Argentina on the Uruguay River. The area is surrounded by grassland which supports vast herds of livestock and has a major deep water port. Logistically it made a perfect place to start a meat processing factory. So back in 1865 a company called Liebig Extract of Meat Company (LEMCO) was founded and began perfecting the production of meat extract and meat processing. In 1899 the company was renamed Frigorifico Anglo del Uruguay.

Uruguay is one of the largest meat producing countries in the world, and raises more cattle per capita of the population than anywhere else. Fray Bentos can be found near the border with Argentina on the Uruguay River. The area is surrounded by grassland which supports vast herds of livestock and has a major deep water port. Logistically it made a perfect place to start a meat processing factory. So back in 1865 a company called Liebig Extract of Meat Company (LEMCO) was founded and began perfecting the production of meat extract and meat processing. In 1899 the company was renamed Frigorifico Anglo del Uruguay.

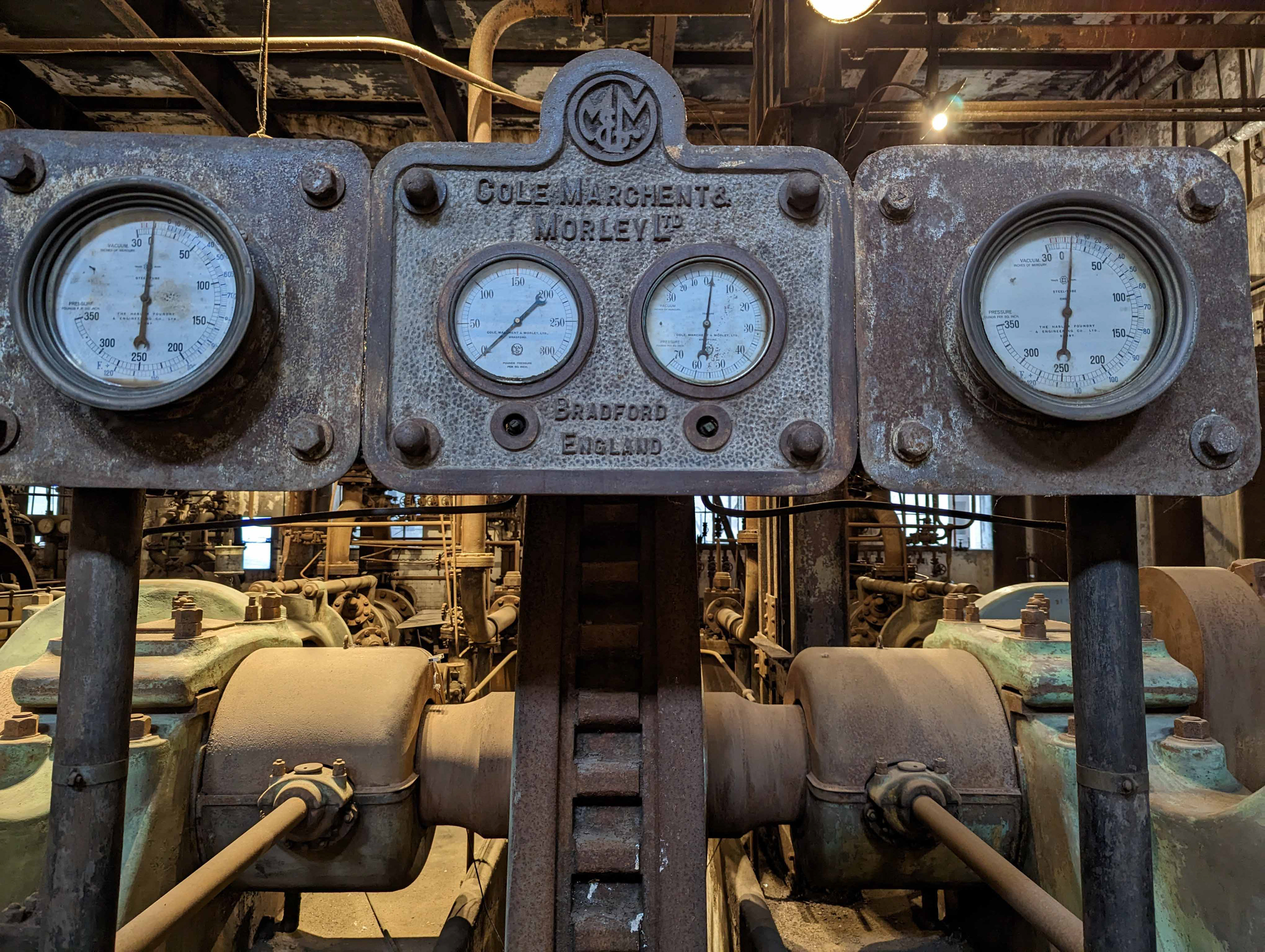

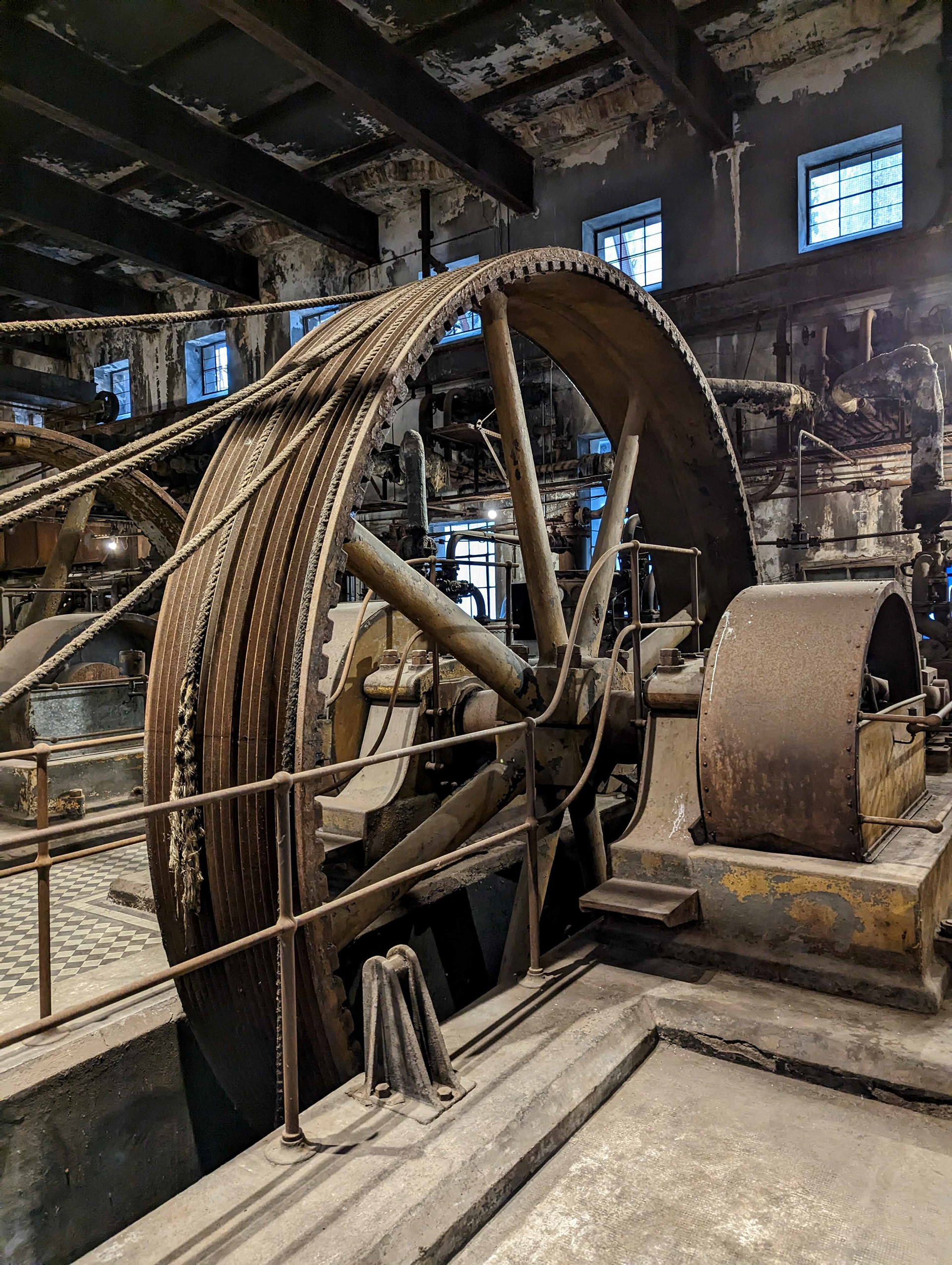

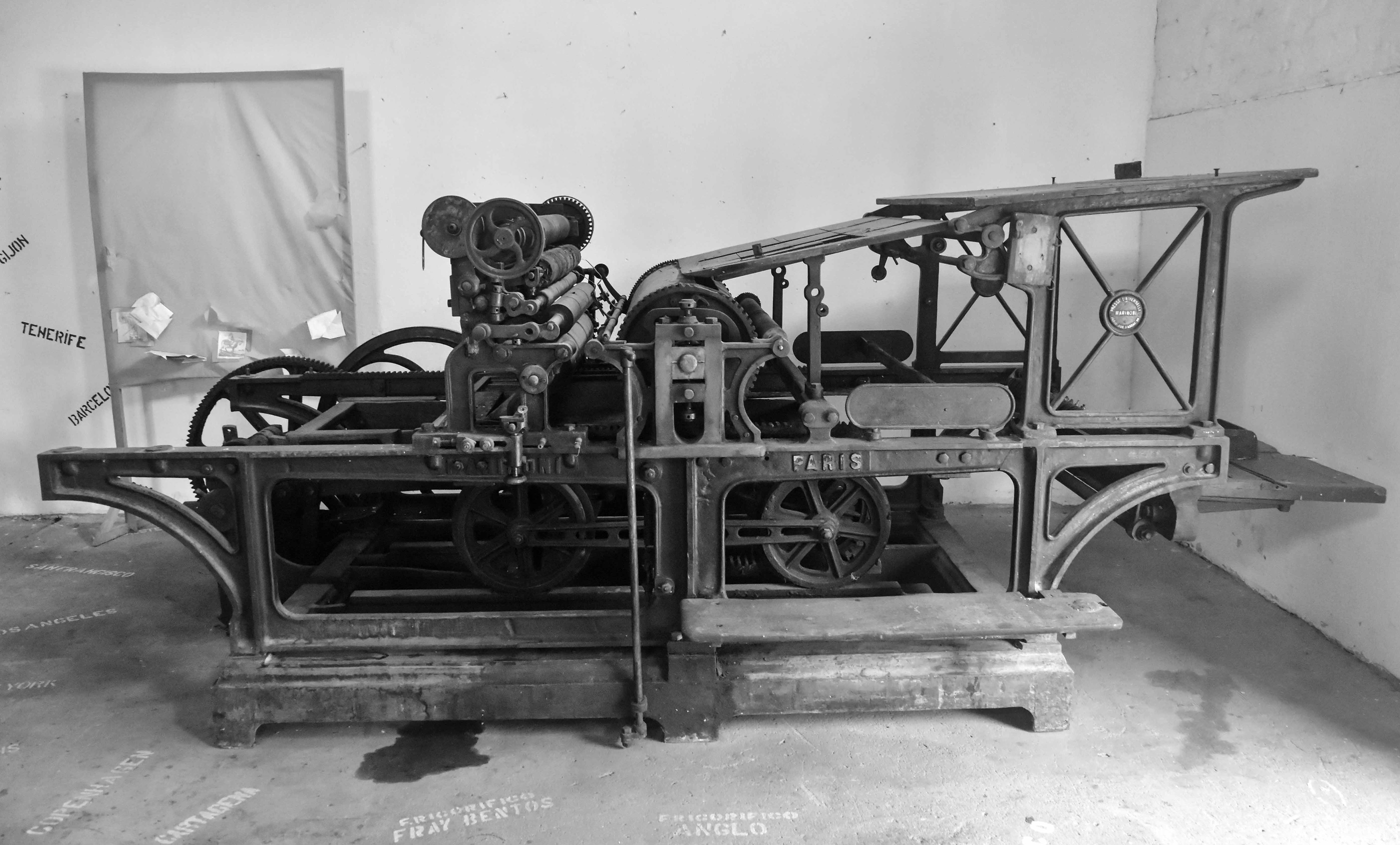

The early products produced at the Fray Bentos site were meat extract in the form of OXO cubes and then corned beef. LEMCO imported technology from Europe and rapidly expanded, becoming a major exporter of meat products to 5 continents around the world. In 1898 alone 450 ships moved through the factory's port, rivalling that of some European cities.

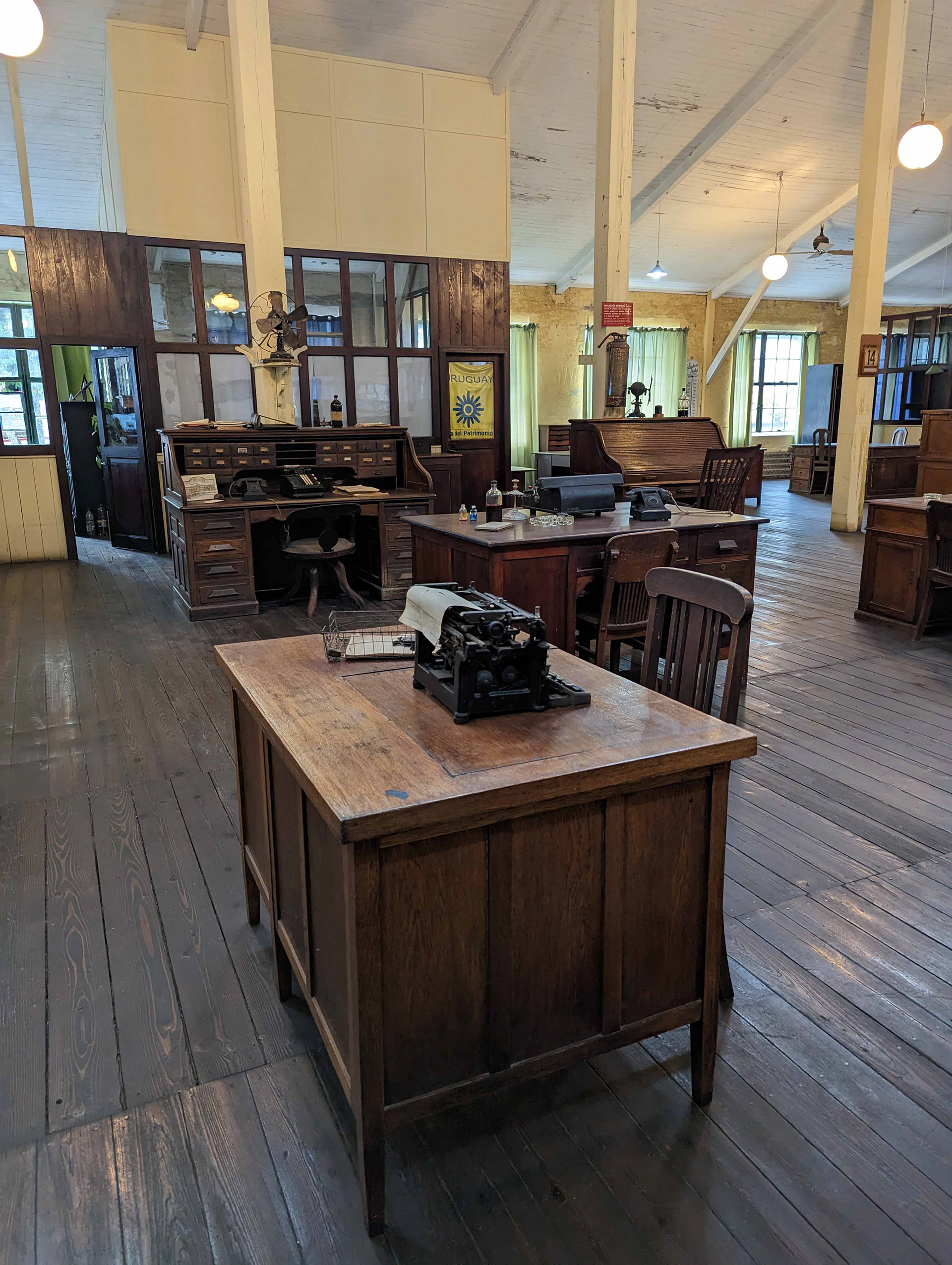

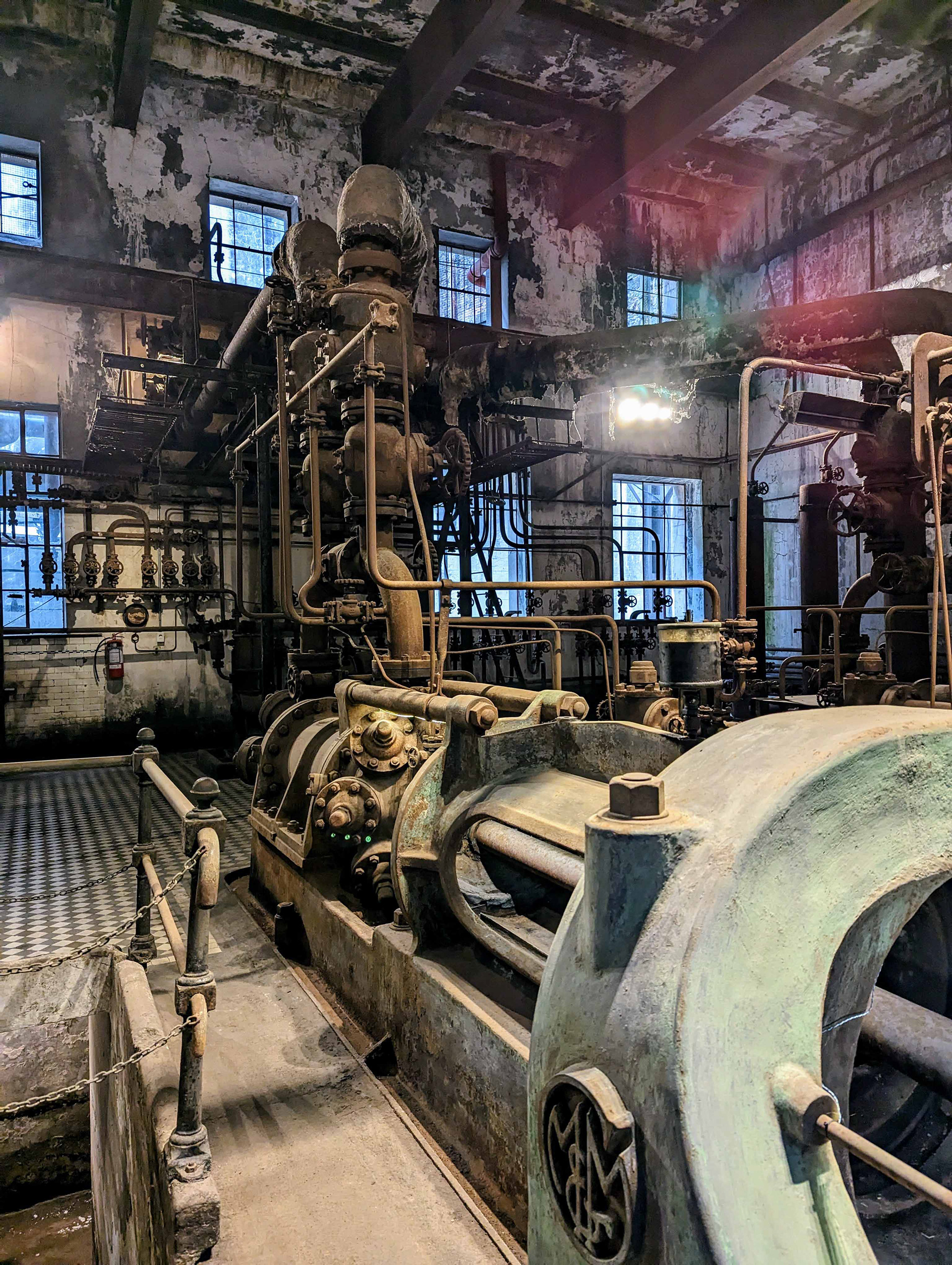

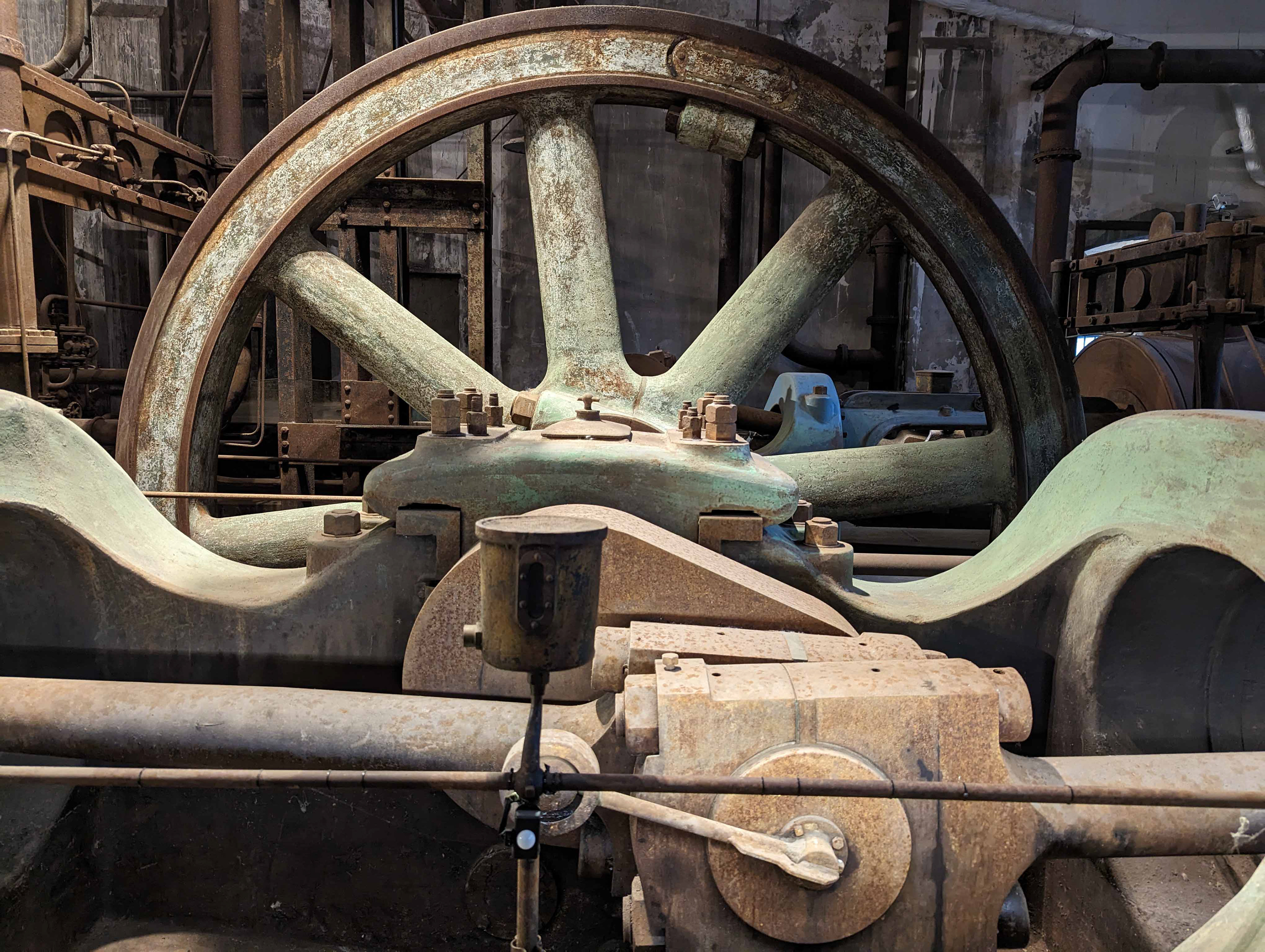

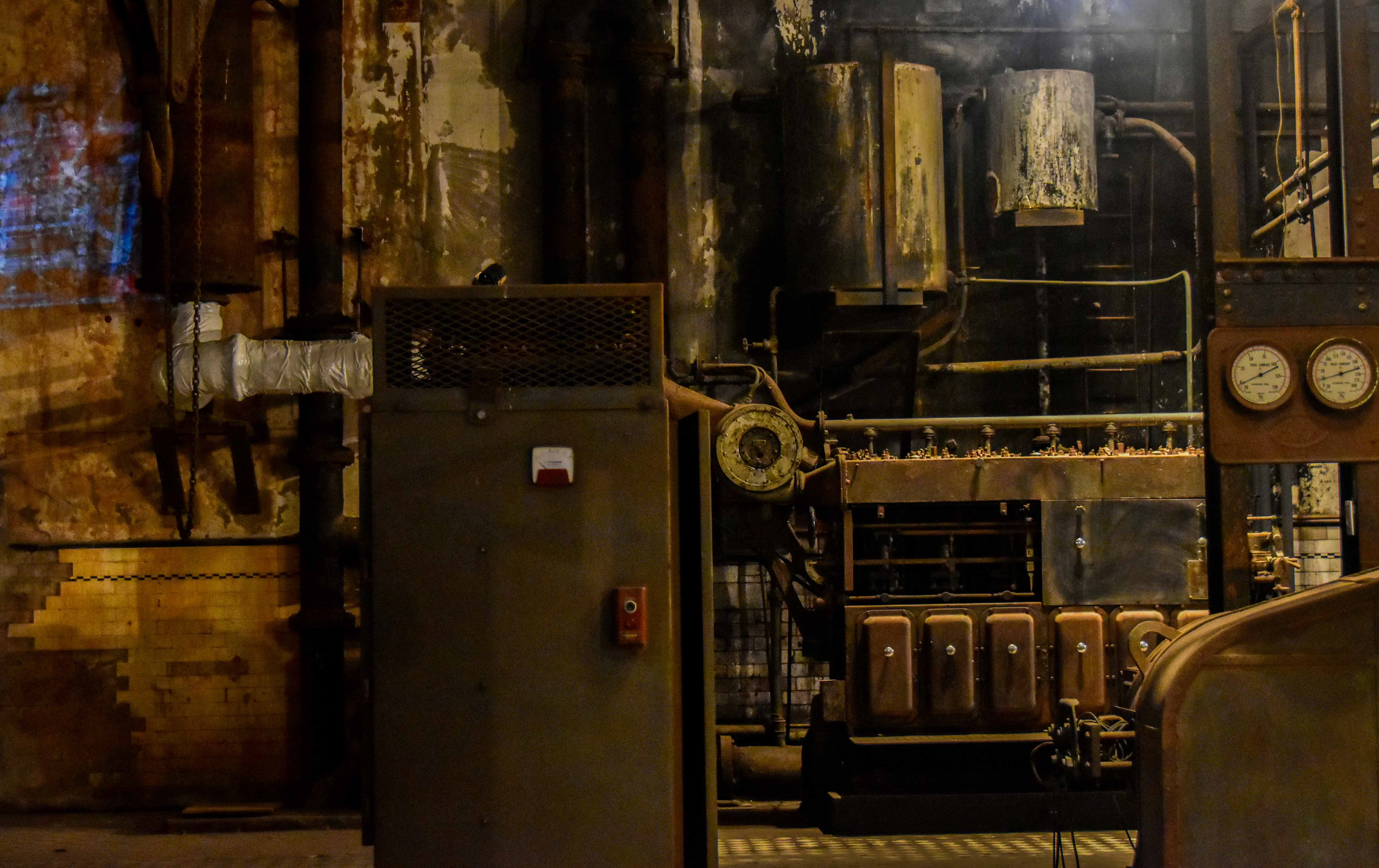

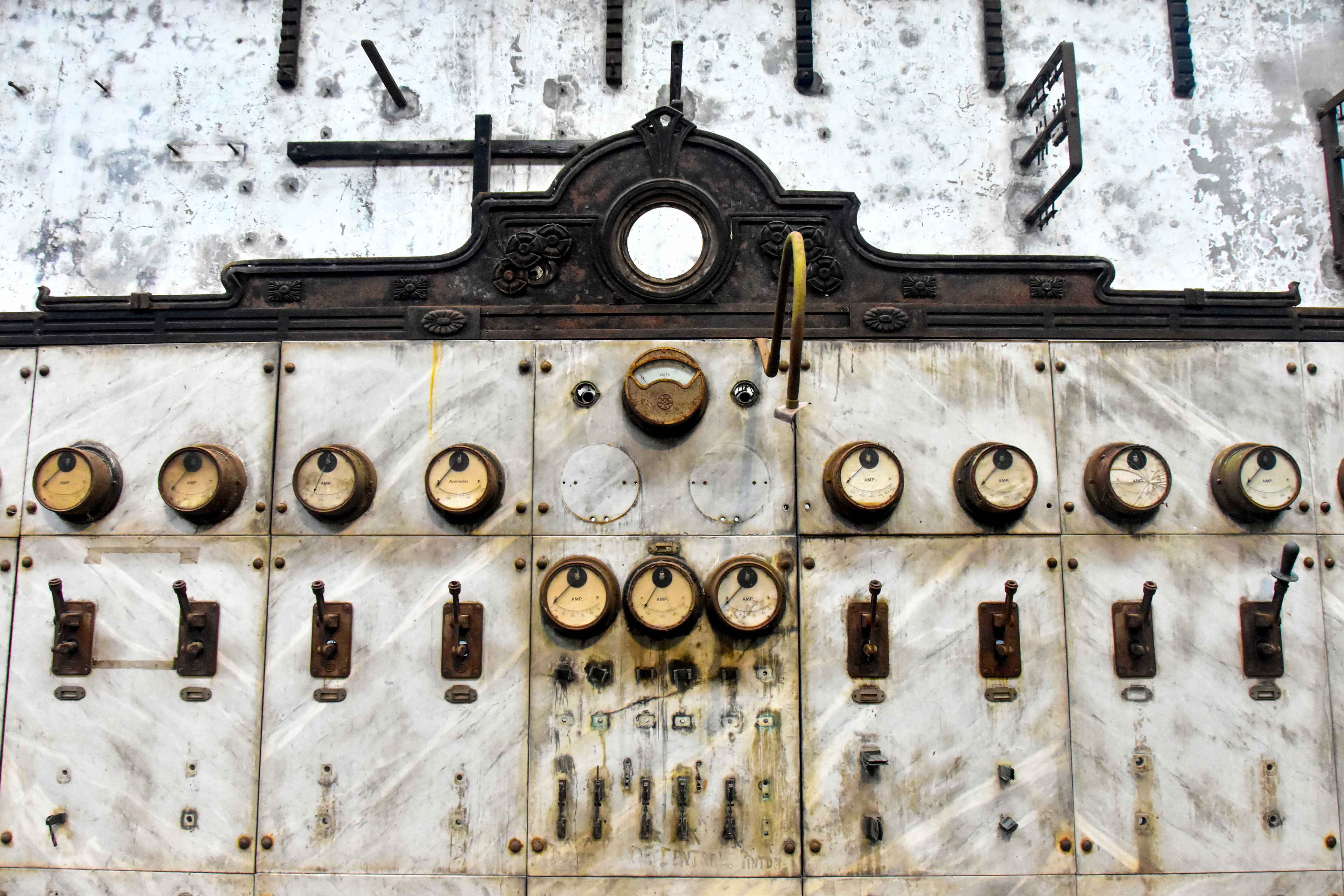

In what seems like 21st century thinking those early owners also looked to improve cattle genetics, pastures and yields as well as the effectiveness of fertilisers along with attention paid to the products nutritional values. The innovation didn’t stop with the cattle. In fact the factory was the first place in Uruguay to have electric light, a whole 3 years before the capital city, Montevideo. This then led to the building of huge refrigeration and freezer chambers so the company could diversify in exporting chilled and frozen raw meat.

In addition to the huge industrial buildings, the complex also included a residential area for the workers called Barrio Anglo. The workers and their families were provided with housing, social, educational and sports facilities. As well as providing jobs for butchers and cattlemen, the factory was self sufficient for a host of other support trades that the factory needed including label making, textile manufacturing for uniforms, carpentry, blacksmiths, smelting and barrel making to name just a few. At the height of production, the factory employed 5000 people in a wide variety of roles and slaughtered 1 cow or 1 sheep every 5 minutes. The process from arrival in the slaughter yard to steaks took 30 minutes. It was boasted that every part of the animal was used except the moo!

In what seems like 21st century thinking those early owners also looked to improve cattle genetics, pastures and yields as well as the effectiveness of fertilisers along with attention paid to the products nutritional values. The innovation didn’t stop with the cattle. In fact the factory was the first place in Uruguay to have electric light, a whole 3 years before the capital city, Montevideo. This then led to the building of huge refrigeration and freezer chambers so the company could diversify in exporting chilled and frozen raw meat.

In addition to the huge industrial buildings, the complex also included a residential area for the workers called Barrio Anglo. The workers and their families were provided with housing, social, educational and sports facilities. As well as providing jobs for butchers and cattlemen, the factory was self sufficient for a host of other support trades that the factory needed including label making, textile manufacturing for uniforms, carpentry, blacksmiths, smelting and barrel making to name just a few. At the height of production, the factory employed 5000 people in a wide variety of roles and slaughtered 1 cow or 1 sheep every 5 minutes. The process from arrival in the slaughter yard to steaks took 30 minutes. It was boasted that every part of the animal was used except the moo!

After the Second World War trading partners changed and the factory at Fray Bentos became less important to the world wide meat trade. In 1979 the doors were closed for the last time, with almost everything left behind inside the building. In 2005 the site was reopened as the Museum of the Industrial Revolution. As so much of the factory’s machinery was left in situ it was preserved and so in 2015 the site earned recognition as a UNESCO World Heritage Site.

The photos I have included below were taken during a guided tour. Sadly our time at the site was limited - I could have been there all day amongst the peeling paint, rust and atmospheric industrial remains.

The photos I have included below were taken during a guided tour. Sadly our time at the site was limited - I could have been there all day amongst the peeling paint, rust and atmospheric industrial remains.